Glass tubing and rod come in four or 5 foot lengths and are measured metric diameters. Five feet of tubing is rather awkward and sometimes a bit difficult to handle in the flame. Therefore cutting the glass down to size will help in managing the glass.The first two methods listed here work well for smaller diameter rod and tubing. For larger diameters consider methods 3 and 4 will almost certainly be required.

Option #1 - Scratch & Snap Glass Cutting Technique

This method works well for beginners, but as you gain experience you will probably end up preferring Option #2 (which is quite similar).

- Make a scratch on the glass wall surface by drawing the corner ideally a tungsten carbide knife perpendicularly across the tube. as shown below:

|

Tip: Do this step once creating a scratch approximately 1/8 inch long. Do not saw the glass. Sawing the glass will not make the process of breaking the glass any easier. It is not necessary to make a long scratch. A short, single sharp scratch is more likely to produce a clean and even edge. |

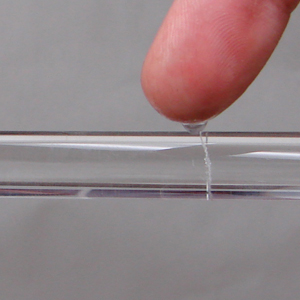

- Grab the glass tube and wet the scratch with your finger using (water or saliva). Turn the scratch away from your body.

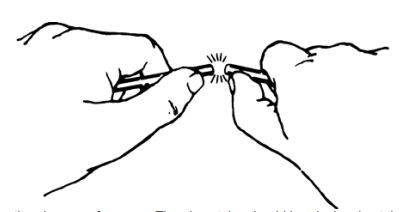

- Place your thumbs on the glass tube or rod. The scratch should be located between the thumbs but on the opposite side of the tube as shown below. With practice, you will find a distance between your thumbs that works for you.

- Push your thumbs away from you. The glass tube should break cleanly at the scratch. Safety Note: You may wish to wear leather work (not latex!) gloves or wrap the glass in a towel to reduce the possibility of cutting yourself.

A

tutorial for this method with step-by-step pictures is available at Robert Hunt's Teralab web site.

Option #2 - Scratch While Holding Then Snap

- Hold the glass tubing one hand.

- Hold your tungsten carbide knife in a vertical position with the other hand. Place the glass tubing between your thumb and knife, holding it firmly - horizontal and close to your body for support and stability.

- Twist the hand with a knife, creating your scratch.

- Break the tubing as described in Option #1, Step 4 (above).

Option #3 - Scratch and Apply Hot Glass

This option is the safest and easiest method if you have large diameter tubing but don't have a glass saw. This method should be only used after you have had some experience handling the torch:

- Scratch the tubing with a carbide knife as described in Options #1 and #2 (above).

- As above, wet the scratch.

- Heat the end of a 6 mm rod until it is red hot. Quickly place the end of the hot rod onto the wet scratch. Be sure the scratch line extends beyond the contact area of the hot rod.

|

Tip: If done correctly, you will observe a crack forming at and extending from the scratch. If the crack does not travel completely around the circumference tap the crack lightly. This action may chase the crack around the tube. Alternatively, reheat the glass rod and reapply to the crack. Again, be sure the rod does not extend beyond the end of the crack. |

Option #4 - Power Tools

If you have access to a

glass saw or cut-off wheel, you may find this to be an easier method. For small and routine work this is serious overkill as it takes a lot of time to clean the glass again.

Option #5 - Hot Wire Cutter

This method is not for beginners. It uses a loop of nichrome wire which is resistively heated by a power supply. The wire is wrapped around the tubing and then instantly brought to red hot. It can be used to cut very large diameter tubing in place (such as on a large vacuum manifold) or to cut very accurate short lengths of glass. Robert Hunt has a

full description of hot wire cutting on his Teralab web site.