Links

.

Glassblowing Tools and Terms

Air Compressor –

A machine that compresses air to be used for blowing, numatic machines, sandblasting, or to cool you off a little. NEVER EVER take the blower end of the machine and stick it up some ones butt. It may sound like a great prank, but that air pressure can kill some one. Don’t do it.

.

Blow Hose –

A hose that a blower hooks one end up to a tube of glass and then the other end goes in their mouth. The blower will use this to blow air into the glass to pop a hole, to keep the glass shaped or to blow the glass larger when heated.

Blow Hose Assembly – This is the blow hose, swivel and mouthpiece all assembled as one unit. These pieces work better as a group then by themselves.

.

Bowl Push –

This tool is used by a blower to make their bowl in a pipe. Some blowers have 3-5 of them. You can make them or buy them. They can be made of graphite or brass.

.

Bucket (Water Bowl) –

The bucket is where our hopes and dreams go on the bad days. Sometimes just a metal bucket and sometimes a metal bowl filled with water.

Water bowl – At our studio we use the water bowl as our main bucket. Then we dump this bowl of the broken glass contents into our larger trash bucket when we clean our stations. The water bowl is used to put hot glass in so it cools off very fast. You must be careful here not to put in too big of a piece of glass that is too hot. There is a lot of energy in this glass and as it cools in the water it pops and explodes, so be careful not to put too big a piece of glass in your water bowl. The water bowl is also used as a shocker to shock a piece of glass rod you use to rip off trash glass. Simply put the hot glass in the bowl, it will crack and pop, then hit the edge of the bowl and your trash will pop off the glass rod. The water bowl works best as a tool when you have it filled to about 1/2″ to 1″ from the top.

.

Calipers –

A device used to measure the distance between two opposite sides of an object. A caliper can be as simple as a compass with inward or outward-facing points.

.

Chucks –

This is the part of the lathe that grasps the glass. There are basically two kinds. There is the scroll check that uses a key to open and close it. Then there is a planetary chuck that uses a plate on the check to open and close the chuck.

.

Claw Tool Holder (Grabbers) –

A device used to hold hot glass.

Standard Claw Tool –

This tool is used to hold say glasses, bases to glass, larger marbles or nearly anything you need to hold that you can not hold with your hand or that you do not want to use a punty to hold the glass with. A standard claw tool is usually made of a handle that has 6-8 hardened wires pressed into it. Then there is a slip ring with a threaded lock on it to hold the wires in place around the hot glass.

Marble Claw Tool –

This tool is slightly different than the standard tool in that the ends are bent in a circle to hold a marble better without it dropping out and edge.

.

Copa Traditional and Triangular –

Often a source of more question than answers, will make an ordinary wrap into a perfect half-round. The diameter and perfection will vary with the size of the wrap and the person using the tool. The triangular copa will make crisp triangular wraps that will vary in size with the amount of glass applied. Augustine Fresnel found that triangular wraps (prisms) have great optical properties.

.

Crimps –

Used in glass to smash or mash the glass. It leaves a pattern in the glass as you press it. Used to texture leaves or make any kind of pattern really.

.

Diamond Shears –

Special pliers with a sharp diamond shaped opening for cutting glass and, typically, a round opening at the tip for controlling punties, pulling glass, etc.

.

Didymium Glasses –

These are the basic safety glasses of the glass industry. They mostly filter the sodium flare and UV rays. These are really only good for soft glass and boro and quartz require a filter that will also filter the IR.

Words of wisdom – Go and get the good ones. Get the darkest you can work in. The more you can filter the better it is for you.

.

Digital Controller (Digitry) –

The Digitry is the standard annealer and/or furnace controller used in modern glass studios. It controls up to five separate annealers and is extremely easy to program and control.

.

Drill Press (Core Drill) –

This is a drill that is made to be more accurate than a hand held drill. For more info on a press see the Drill Press link

.

Dust Mask (Respirator) –

These tools are very important when working with any kind of dust. If it is a light dust you can get away with a dust mask. But if you want to be really safe, spend the extra money and get yourself a respirator. It will last a long time and is a better filter. Be safe, its your health and your going to live longer than you think.

.

Etching Cream –

Etch All is the re-usable liquid glass and mirror etch. Chemically etch your glass beads to produce a soft velvet matte or satin finish and look. Your finished product will be fingerprint proof and able to retain oil or acrylic paints and inks. Complete instructions are provided on the bottle for a quick 15 minute etch! Works great on all glass, mirror, ceramic, porcelain, marble, or slate products. Does not work so good on borosilicate glass

.

Exact Torch –

The Exact torch is the standard high-pressure torch used in glassblowing to heat specific parts of a work-in-progress. It is a modular system with interchangeable heads that go up to about 400,000 BTUs.

.

File –

A device used to scrape off metal and can also be used to notch glass. Its a great handy tool to get you some silver shavings so you can do some universe marbles. These small shavings help give you that comment effect.

.

Fin Mold –

If you’re ready to take on the tricky world of faceted goblets you might consider a Fin Mold. Once you learn to master it, your patience will be rewarded with crisp facets. Fin Molds come in four different profiles with stainless steel construction.

.

Flare Tool –

A flashback arrestor or flash arrestor is a special gas safety device most commonly used in oxy-fuel welding and cutting to stop the flame or reverse flow of gas back up into the equipment or supply line and it prevents the user and equipment from damage or explosions.

.

Flashback Arrestor –

A flashback arrestor or flash arrestor is a special gas safety device most commonly used in oxy-fuel welding and cutting to stop the flame or reverse flow of gas back up into the equipment or supply line and it prevents the user and equipment from damage or explosions.

.

Foot Pedal –

A device used to usually turn the outer flame off on a larger bench torch. This is one of the best upgrades a blower can do for themselves. Two of the top brands we have seen over the years are the super reliable set from Griffin Glass. The other is also great from Jeff Rogers.

.

Fork (Pastorale Fork) –

The fork is a long metal rod with a forked end on it, used to load work into either a garage or annealer. The fork is typically used when making goblets and other Venetian-style work.

Info by David Patchen

.

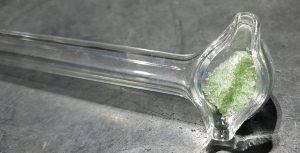

Frit Maker (Crusher) –

This is a device you can use to smash glass into small pieces called frit. Basically a tube with a bottom that can hold the glass. Then another tube with a metal part to smash and a handle on it. Put the glass in, lift the handle up and let is smash the glass, now you have frit you will have to sift.

.

Glass Gong –

This is used on rare occasions when something very very special happens. It may only be rung 20 times a year. The higher your skill set, the harder it is to obtain a GONG.

.

Glass Rod Warmer –

This tool is used to pre-heat your glass rods. This allows you to get them molten much faster, while also saving fuel and oxygen.

.

Glory Hole –

These furnaces are mostly gas-fired and are used to reheat work that in in progress. They can range in many sizes from commercial use to home use. The doors on the front can be moved to accommodate larger glass going in and out of he glory hole. Used mostly in soft glass, but sometimes in boro glass. Marcel is the guy in the borosilicate world breaking the rules with these things.

Do not get this glory hole confused with those other glory holes found in bathrooms. Just not the same, stay away from the bathroom glory hole, you may get some fire there, but its not good fire.

.

Graphite –

Basically carbon, it is the most stable form of carbon under standard conditions.

Graphite by a blower – This will be found in any blowers arsenal. Usually it will be in flat plates that a blower will roll their glass on, or it will be in the form of a rod. The graphite can withstand shit tons of heat and can also be put in water without damage. Its easy to grind or carve for a simple mold.

.

Ground Glass Forming Tool –

This is used to make those ground glass joints. Basically it is a tool that has a mold on the inside and two parts on the outside to mold the glass. As you heat up the tube you insert the tool into the hot glass tube and then press the outside to get the shape of the tool. Here is an example of an Elev8 Premier tool we make our joints on.

.

Gun Case –

A plastic case that has foam inside to protect the contents. They work perfect for glass.

Graphite by a blower – This is used to take all your glass to the sell it. As a blower you will need to learn to sell what you make. People only by from people that are selling. This is a very inexpensive tool that if you treat it right will last a long long time.

.

Heat Protection –

You need this when you go big. There are a lot of different kinds of protection from sleeves, leather vests, full metal jackets. The harder you go, the bigger the flame, the larger the radiant heat, the more protection you need.

.

Hose –

This is what a blower or welder uses to hook up their oxygen tanks to their torches. The red is used for fuel and the green is for oxygen. There are different grades of these hoses, so make sure you know what you are looking for and talk with your welding supply store. We know grade T will work for propane.

.

Hose Clamp –

This is used to secure your hoses to your connections. Any time you make a connection you should spray it with soap to make sure you are 100% good to go.

.

Hot Fingers –

These are also called claw grabbers or holding clamps. See also holder or claw fingers for more styles.

.

Hot Plate –

Electric and gas hot plates have many uses in a hot shop. They are used most frequently to preheat bits of color or murrini so that the color does not crack upon contact with the work-in-progress.

.

Implosion Tool –

In the flower industry they call this a frog. Ya, a strange funny name for such a tool. Basically a tool that has a bunch of pin in pattern.

Implosion Tool by a blower – This tool is used to get all those neat implosion style marbles. Simple gather some hot glass and then push it down on this tool. It will put a bunch of indents in the glass. You then take some color or fume it and then add clear to all the pushed indents.

.

Infrared Heater –

A device used to heat up the studio. Because the air flow is so great standard heaters will not work as they heat the air and it will go right out the exhaust. Elev8 Premier has invested in these to keep the super cold winter days workable.

.

Kevlar (Sleeves, Gloves, Pads) –

This has many applications, ranging from bicycle tires and racing sails to bulletproof vests, because of its high tensile strength-to-weight ratio; by this measure it is 5 times stronger than steel. It is also used to make modern drumheads that withstand high impact. When used as a woven material, it is suitable for mooring lines and other underwater applications. In glass we use it becuase it also has a high temperature rating. We use it for sleeve, gloves and pads.

.

Kiln –

A high temperature oven for annealing glass. These can get up to temps in the 1000’s of degrees F. They range in size from small tool box sizes to where you could drive a car into. Depending on the project dictates what size kiln is needed.

.

Kiln Posts –

These are used to hold up a kiln shelf, keep a tube held up, or we even use it to keep the kiln door better closed during the annealing process.

.

Kiln Wash –

A kiln wash is a sacrificial layer of material between your glass and your kiln shelves. It’s primary purpose is to prevent glaze from sticking to your shelves. The ingredients are materials with high melting points, with the formula adjusted based on what temperature you are firing to.

.

Knock Off Table –

The knock off table is an essential piece of hot shop equipment for making production-line work. It is covered with a woven silica fabric that can stand the heat of a freshly made piece and will not wick enough heat from the piece to cause a check. A piece can be knocked off onto the table, and then a torch can be used on the punty spot to soften any sharp edges before the piece is placed into the annealer.

.

Lab Coat –

At Elev8 Premier we use the lab coat when we are working in the wet room. We use this for when we are grinding or cutting glass on the lapping wheel or on the wet saw. Glass dust gets trapped in the water, this is good! The issue that can arise is that when the water dries you have a bunch of glass dust on your clothes. We use this to catch that water dust and then wash it after each use. Always where a dust mask while grinding or cutting also.

.

Lapping Wheel –

This is a tool used to make glass flat. Many times it is used to facet glass into beautiful shapes like a diamond, or to make a piece of glass sit flatter. A lapping wheel is made from a rotating wheel covered with an abrasive, usually diamonds. When grinding on a wheel you will want water to always run on it as a lubricant and to keep the glass dust down. Always wear a dust mask.

.

Lathe for Glass –

This is a machine that spins the glass for the blower. A glass lathe is unique in that it spins the chucks on both sides of the lathe, while wood and metal lathes only spin on chuck. As the glass gets soft it needs to spin as the same speed on both sides. So with both sides of the lathe spinning it allows you to work a glass tube or rod uniformly.

.

Glass Blowers Lazy Susan –

This is an amazing tool if you can swing it. We made our own here at Elev8 Premier as who does not need more space?? Put your frit in it, small tools, sunscreen or I bet you can think of all kinds of things.

.

Lighter (Zippo, Striker) –

This is the tool used to start the fire on your torch. NEVER USE A BIC OR ANY KIND OF BUTANE LIGHTER. These can explode when they get hot. Get some style and get a dope ass zippo. If you find a zippo you like, Elev8 Glass Gallery can even get it engraved for you.

.

Local Exhaust Ventilation –

One of the most important tools to the blower. This needs to be strong enough to move the air and make sure that if you are doing any fuming all the extra fume is removed from your surroundings. The rule of thumb is that it will be able to pull up some toilet paper from your hand into the exhaust. Go bigger than smaller.

.

Mandrel –

A round object against which material can be forged or shaped. Usually made of graphite in this industry. Below is an example to of a ring mandrel.

.

Mandrel Rack –

This item is used to rest mandrels on. Sometimes used next to a kiln so the beads can sit in the kiln and the handle on this rack.

.

Marble Mold –

A marble mold us mostly always made from graphite for the ease of machining the graphite along with the high temperature resistance it has. They come in many shapes sized and styles. Here are some of what Elev8 Glass Studio uses in house.

.

Marble Tongs –

A tool that is designed to grab a round marble where tweezers will let the marble fall. Usually much like a pair of large tweezers but on the open end there is a ring.

.

Marver (Paddle) –

A surface, sometimes with with grooves, which hot glass is rolled to shape it and smooth it out. Usually made from graphite to withstand the extreme heat of the glass.

.

Masher –

Used in glass to smash or mash the glass. There are many many different kinds. The most common mashers are used to mash a round ball of glass into a disc.

.

Mold (Mould) –

A hollow container used to give shape to molten glass or other liquids as it cools and hardens. Many times soft glass is blown into a mold, below is a bottle mold.

.

Necking Tool –

These tools are super great for creating very tight shaping and restrictions in blown or solid glass.

.

Nippers –

This tool is used to break off small piece of glass. Some nippers have a cutting wheel or wheels built into them for cutting glass even better. Some people use a tile nipper for this purpose.

.

Nuggets –

This is the herb that a typical glass blower will consume throughout the day. Many people call this cannabis or ganja.

.

Optic Mold –

A open, cone-shaped mold with ridges on the inside that will impart a pattern on the surface of a gather or bubble that is inserted into it when hot.

.

Oxygen Regulator –

Oxygen Regulator

This device lets the oxygen run at a nice steady level so the flame works consistently. Mostly it will be used to lower the pressure and keep it steady. Many times if using a K tank or dewar tank the pressures can be 300-2000 PSI. Our GTT torches run on 12 PSI

.

Oxygen Vaporizer –

A device that is connected to an oxygen dwer when you run liquid from it. This allows the liquid to expand and give good pressure on larger setups.

.

Pick (Rake) –

A rod of metal that has a point ground on it. Used to press into the glass.

Tungsten Pick – This amazing tool is used to move or sew small amounts of heated glass and is most often used to help close small openings found during glass repair or fabrication. One really neat thing that can be done with this tool is that you can slightly heat your glass. Then with just the pick going in and out of the flame (not to heat it too much) so it is red hot but not melting you can push it threw hard glass.

.

Pi Divider –

A Pi Divider is a mechanical calculator that determines the size of a post needed to pick up a number of canes. The canes are then lain out on the plate and then measured with the straight arms of the Pi Divider. The curved end will indicate the size of the post.

.

Pipe Cooler –

As the blow pipe is used, heat travels up glassblowing pipes and punties. The pipe cooler sprays water onto the pipe to cool it. It is important to keep the pipe turning when using the pipe cooler or the pipe could warp. Pipes should be cooled from the cool part first and then up towards the moil.

.

Pistol Grip Glass Cutter –

This tool is used to cut sheets of glass. Many blowers will use this to cut sheets of dichroic glass. This tool features a self lubricating cutting wheel. Cutting oil is a good thing for these and that is why they are designed to be used with the oil. The oil helps make a cleaner cut.

.

Propane Tank –

This is the tank that holds your fuel called propane, just that simple. They come as 20 and 40 gallon set ups that you can easily get at a Home Depot, or you can go much larger to 1000’s of gallons. We use 4 at a time in a bank at our Elev8 Premier studio with 2 of these sets.

.

Rack –

This is a tool that is used to store parts. These parts can be tool, prototypes, samples or really anything. Racks are great as they use vertical space in small floor footprint.

.

Razor –

An instrument with a sharp blade or combination of blades, used to remove unwanted hair from the face or body. Used to make thin lines in molten glass.

.

Reamer –

This wonderful tool (a must have in any studio) can be made from metal (usually brass) and graphite. Usually it is a long point and is made by grinding down 8 sides sometimes 6 sides. It can also be smooth. We prefer the octagonal.

.

Ring Tool (Ring Mold) –

The marvel of marbles is now made significantly simpler. To make a sphere, just grab your trusty Ring Tool or Ring Mold and run it around the bit as it rolls back and forth on the bench. After a few passes, you’ll have a new perfect marble. This is works much like a marble mold.

.

Rod Holder –

A metal rod with an and that will except a rod of glass. There different styles available, you will have to find what you like and what works best for you.

.

Rod Rack (Tool Holder) –

A device used to hold your hot glass tips off the bench so they do not cool too fast and crack. You can also rest your tools on there as well.

.

Rollers (Bench Rollers) –

A device used to hold a tube or rod of glass.

From a blowers points of view – So this can help you become a human lathe. The yoke style or rollers with just two rollers are used more for holding rods or tubes while you work the glass. The rollers that have rows or rollers or are just a long roller are mostly used for when you are using a mold. Elev8 Premier uses the rollers with rows for making our ground glass joints.

.

Rolling Yoke –

A rolling yoke is a necessity when making larger scale or heavier pieces. The gaffer can move the yoke towards the gloryhole as needed to help manage the weight of the piece.

.

Safety System –

Modern studios add safety system to the combustion train of each piece of equipment. The safety system shuts off the equipment if any sort of fault is detected. There are shutoff valves that activate if the gas pressure is too low, too high, or if the flame goes out.

.

Sandblaster –

A machine that uses air pressure to shoot sand out of a nozzle and onto the piece you are working on. Not always do you really use sand. Here at Elev8 Premier glass studio we use aluminum oxide. This is the standard today. When you use this machine you will want to wear a respirator just encase and sand, aluminum or glass dust escapes.

.

Scoop –

A small spoon to scoop frit from a container and then pour it into the glass you are going to work. Most scoopers are made by the blower and have a pouring end to help the frit pour more directly.

.

Sculpting Tool –

This is a tool not used in the flame, or very very rarely, so I would say it is not. These can be from picks, to knives, to presses. Really any kind of tool that is used for sculpting is a sculpting tool.

.

Shears for Glass –

A pair of scissors that is designed to cut glass. NO you can not cut hard glass, but you can cut the glass once you have it molten, and maybe just a little after that as it hardens up.

.

Sifter –

Used to sift crushed glass. Many glass companies will crush the glass into frit with a frit crusher, then they sift it with different mesh sizes to get you what you want for you work.

.

Soap –

We use this to find leaks in our lines. We will a bottle of part soap like Dawn and part water. Spray this on any connection you make to guarantee you have no leaks.

.

Sophieta –

This tool is used to inflate a vessel after is has been removed from the blow tube. Many times the piece is then attached to a punty so that the blower and work the glass. As the vessel heated, the conical nozzle of the sophieta is inserted into the vessel’s mouth so that the blower can put pressure into the glass object he/she is working on.

.

Spray Bottle –

We use to fill with soap, Windex or CLR to clean things.

Titanium Pen by a blower – This is a valuable tool for all kinds of things. You need one filled with saop to find leaks. You need one filled with windex or a glass cleaner to clean your glass. You need one filled with bathroom cleaner to keep that bathroom tidy.

.

Stem –

The stem connects the foot of a goblet to the bowl. This is a traditional chicken-leg shaped stem. Most of the creativity in Venetian goblets is expressed in the stem; animals, flowers and fancy bitwork are common.

.

Stopper –

These are used to plug tubes. They are also used to allow your blow tube to hook up to your glass tube via swivel.

Difference of stoppers – Multi-stoppers are manufactured of red silicone rubber and green neoprene. The rings are cut from the same stopper, each ring fitting perfectly inside the next. This allows for vacuum tight fit for all openings within stopper size range. Ideally suited for glass working operations and chemistry labs. Multi-stoppers made of red silicone rubber are suitable for higher temperature applications with a serviceable temperature range from -100F to +450F. These stoppers are resistant to hot oils, fuels, oxidizing chemicals, sodium hydroxide and ozone. Multi stoppers made from green neoprene rubber have better aging characteristics than those of natural (black) rubber and are resistant to oils, solvents, ozones and hydrocarbons. The serviceable temperature range is from -40 Degrees C to +100 Degrees C.

.

Stump Sucker –

The Stump-sucker is a very neat and clever tool. Its a very simple and inexpensive graphite tool that uses suction to encase objects in clear glass.

How it works: the object is placed in the graphite chamber, heated with a torch, and then covered by a molten mass of clear glass. Using the hose with mouthpiece, the artist becomes the vacuum pump, sucking through the hose to pull clear glass around the object being encased.

.

Swivel –

This tool is used with a blow tube and usually some kind of a plug like a cork, silicon or rubber style. This allows the blow tube to not kink up from spinning the glass.

.

Tape Measure –

An instrument used to get measurements. In the USA most are done in AS (we call inches). But now a days you can find them that read both AS and Metric.

.

Tile Saw (Wet Saw) –

This is a machine that holds a diamond blade used to cut very hard materials such as tile and glass. These are best to always run with water to keep the dust down and to keep the blade and material cool as it is cut. The finer the grit on the blade, the finer the cut will be. Some blades are so clean they do not boil when you fire polish them.

.

Timer –

We use this to keep track of how long a project takes us. If you do not know its hard to know if you are improving, or what to charge. We have one of these at each station.

.

Titanium Pen –

A piece of metal ground or filed to a point.

Titanium Pen by a blower – This used to sign a blowers art. The glass must be wet to write with the piece of metal. It leaves a mirror like signature when used properly.

.

Tongs –

There are used to grab and hold hot glass. They are basically normal cooking tongs, but wrapped with some fiberglass to keep from scratching the hot glass.

.

Torch (Hand Torch) –

An open flame for heating up glass directly.

Torch explanation by a blower – This is the thing that gives us the fire and allows us to melt the glass. There are tons of torches out there. First a blower in this industry needs a bench top torch, then a great addition is a hand torch for getting in all the places you can not get to with a bench torch.

Hand Torch – This is a little smaller torch a blower uses while they are holding the torch in their hand. Hense the name hand torch.

Torch Brands:GTT–Carlisle–Nortel–National–Bethlehem–Herbert Arnold

.

Tweezers –

Special tongs for glassblowing that are long, wide-spread, and have bent tips for fine gripping.

Standard Tweezers by a blower – These are used for grabbing bits of glass whether molting or hard.

Peter Tweezers by a blower – These tweezers are great for making loops and holes for pendants, vessels and buttons. To make loops and holes: place a small amount of glass shaped like a tall bump at the desired location. Heat up just the bump to just shy of it melting down. Quickly place the points of the tweezers to the center of the heated bump and squeeze together. As soon as the tips touch, move the handle back and forth a couple of times in a motion that makes the points rotate in the center of the hole. This motion breaks apart the fine web that would otherwise bridge across the middle of the hole. Remove the plyers and reheat the glass area making up the hole, being careful not to melt the hole closed. Again place the tweezers in the hole and stretch out the hole to the desired size and shape. To make a large loop, simply start with a larger bump of glass. You may also need to reheat more than one time. For a wider loop, start with a bump that is slightly oval shaped at its base.

Squeezer Tweezers by a blower – These are used to open holes further without smashing the glass, but stretching it out rather.

Hemostat Tweezers by a blower – These are used to grab marbles.

.

UV Flash Light –

This is a flashlight that emits ultra violet light. We have found the best nano-meter wavelength is from 365 to 380 to see UF reactive glass.

.

Veri-Flame –

This is the brain that controls the safety system. The Veri-Flame system is the standard used at most glass studios, though there are other manufacturers. Veri-Flames are relatively simple and economical.

.

Vermiculite –

A hydrous phyllosilicate mineral. It undergoes significant expansion when heated. Exfoliation occurs when the mineral is heated sufficiently, and the effect is routinely produced in commercial furnaces. Vermiculite is formed by weathering or hydrothermal alteration of biotite or phlogopite. Large commercial vermiculite mines currently exist in Russia, South Africa, China, and Brazil.

Vermiculite by a blower – This stuff is used to let the glass cool slower than sitting in the air. This is for say small marbles that you do not want to anneal in the kiln. You can get away with this method of annealing, but in a kiln is best.

.

Vice –

A metal tool with movable jaws that are used to hold an object firmly in place while work is done on it, typically attached to a workbench.

.

Wood Block –

Used as a great tool to hold your glass. Unlike a brick you can drill it out how your like. Be careful not to burn it, but if you do a little, it sure smells good? We recommend a larger piece of wood for the weight. The weight is very important. You can also screw these too you table.

.